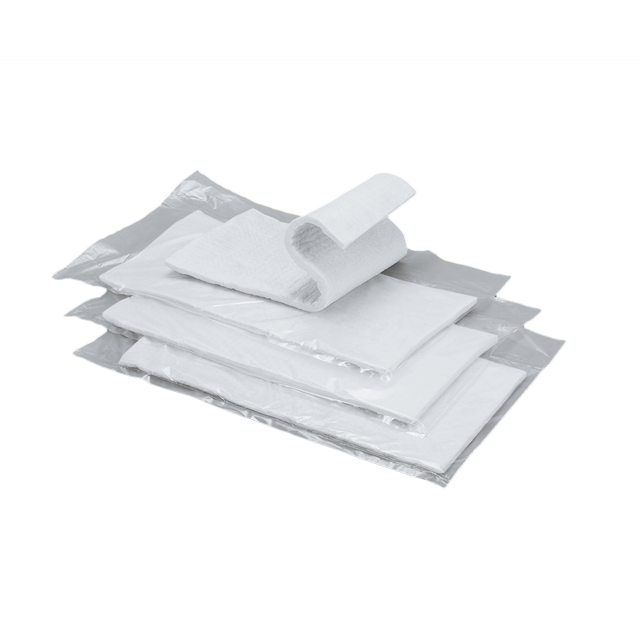

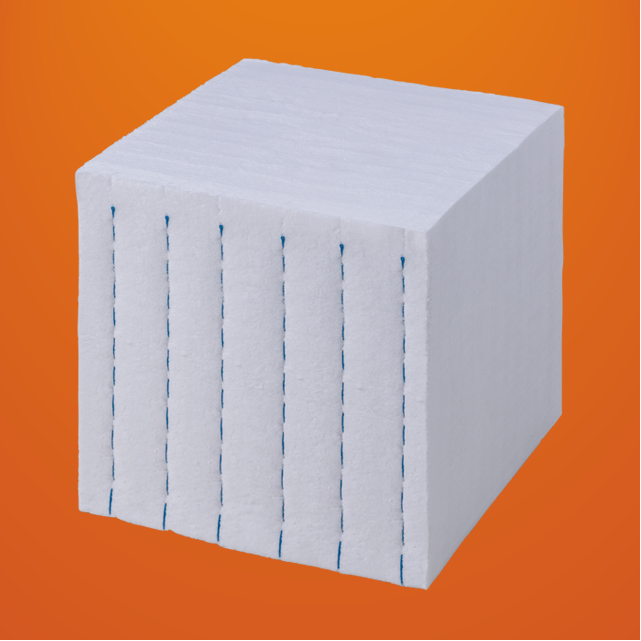

ISOWOOL BLANKET

High Temperature Refractory Ceramic Fiber Blanket

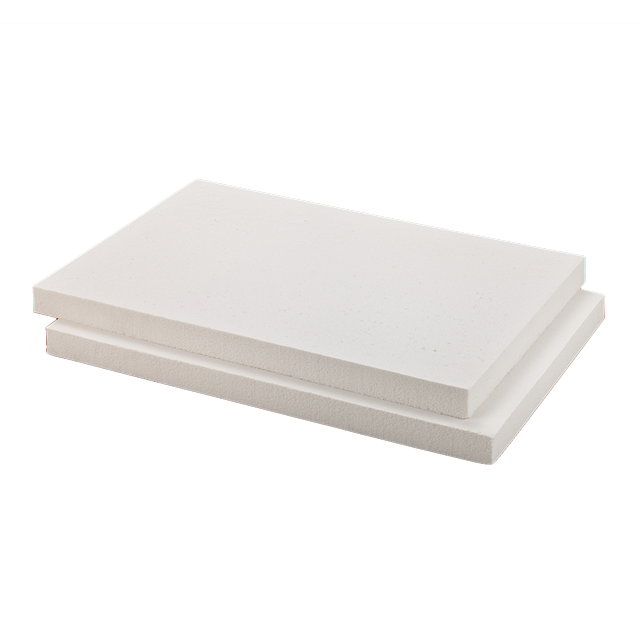

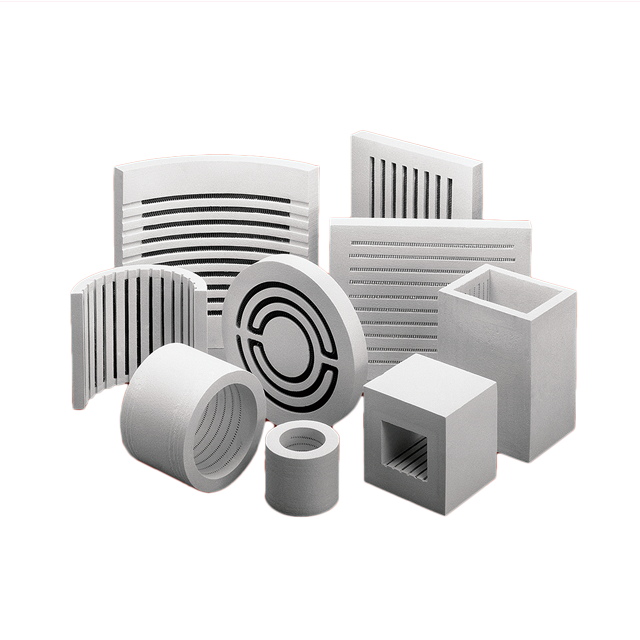

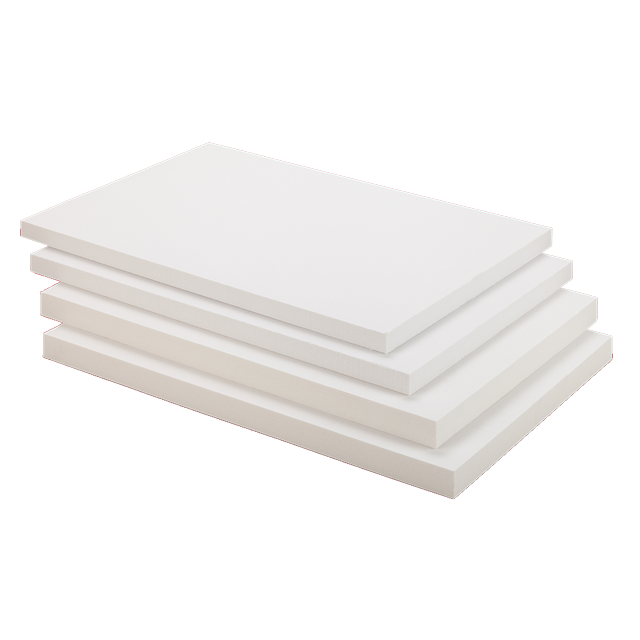

ISOWOOL Blanket is a refractory ceramic fiber featuring light weight, flexible, excellent insulation and heat resistance. Needle punching is carried out while laminating fibers in a layered manner in the manufacturing process, and the fibers are entangled intricately and kept in a blanket shape. Without organic binder, the blankets cause no tearing off at high temperature, nor atmospheric contamination inside the furnaces. As an applied product, it is also possible to manufacture custom-made shapes, such as die-cut products that have been die-cut to predetermined shapes in advance for use as packing materials.

Typical Applications

- Back-Up insulation for the industrial furnaces (Industry: steel, nonferrous metals, glass, ceramics, petrochemical, semiconductors, cement etc.)

- High temperature sealing material such as ladle lid, duct connecting part etc.

- External insulation such as boiler, turbine, duct and piping, precision casting shell etc.

- High temperature gas filtration material, high temperature part sound absorbing material.

- Noncombustible materials for building.

Quality

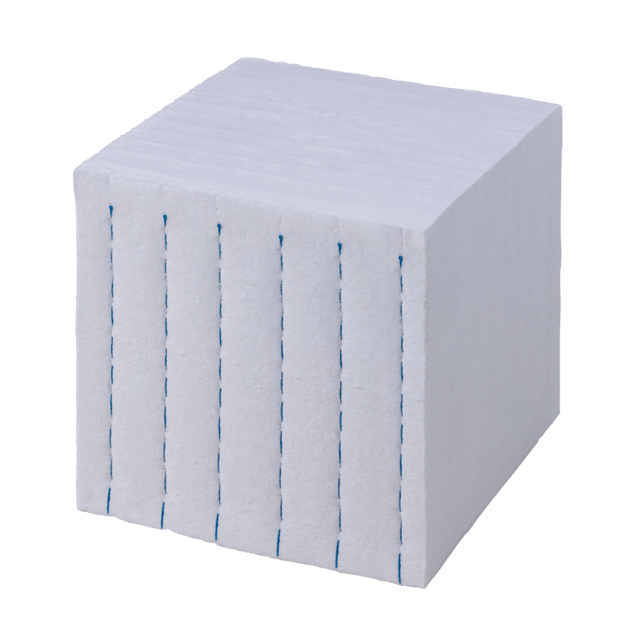

・Ace blanket is a ceramic fiber blanket with improved tensile strength by special needle punching treatment.

| Product Name | 1000 | 1260 | 1260 | 1400 | |||||||

| BLANKET | BLANKET | ACE BLANKET | BLANKET | ||||||||

| 100 | 130 | 100 | 130 | 160 | 130 | 160 | 100 | 130 | 160 | ||

| Max. Service Temperature (°C) | 1000 | 1260 | 1260 | 1400 | |||||||

| Bulk Density (kg/m³) | 96 | 128 | 96 | 128 | 160 | 128 | 160 | 96 | 128 | 160 | |

| Thermal Conductivity (W/(m・K)) 128 (kg/m³) JIS A1412–1 *Calculation value |

at 300℃ | 0.10 | 0.09 | 0.09 | 0.08 | 0.07 | – | – | – | – | – |

| at 400℃ | – | – | – | – | – | 0.09 | 0.09 | – | – | – | |

| at 450℃ | 0.15 | 0.13 | 0.13 | 0.11 | 0.10 | – | – | – | – | – | |

| at 600℃ | 0.21 | 0.20 | 0.18 | 0.15 | 0.14 | 0.15 | 0.14 | 0.18 | 0.15 | 0.14 | |

| at 800℃* | – | – | – | – | – | 0.22 | 0.20 | 0.26 | 0.22 | 0.20 | |

| at 1000℃* | – | – | – | – | – | – | – | 0.37 | 0.31 | 0.28 | |

| Linear Shrinkage (%) | at 900℃×24h | 1.4 | – | – | – | ||||||

| at 1100℃×24h | – | 1.8 | 1.8 | – | |||||||

| at 1200℃×24h | – | – | – | 1.5 | |||||||

| Chemical Composition (%) | Al₂O₃ | 42 | 46 | 46 | 35 | ||||||

| Al₂O₃+SiO₂ | 97 | 99 | 99 | 84 | |||||||

| ZrO₂ | – | – | – | 15 | |||||||

Standard Size (mm)

|

Product Name

|

Size (mm) | |||

| Thickness | Width | Length | ||

| 1000 BLANKET | 100, 130 | 25 | 600 | 7200 |

| 50 | 600 | 3600 | ||

| 1260 BLANKET | 100, 130, 160 | 6, 12.5, 25 | 600 | 7200 |

| 50 | 600 | 3600 | ||

| 1260 ACE BLANKET | 130, 160 (thickness 6mm is not available for 130) |

6, 12.5, 25 | 600 | 7200 |

| 1400 BLANKET | 100, 130, 160 (thickness 6mm is not available for 100) |

6, 12.5, 25 | 600 | 7200 |

| 50 | 600 | 3600 | ||

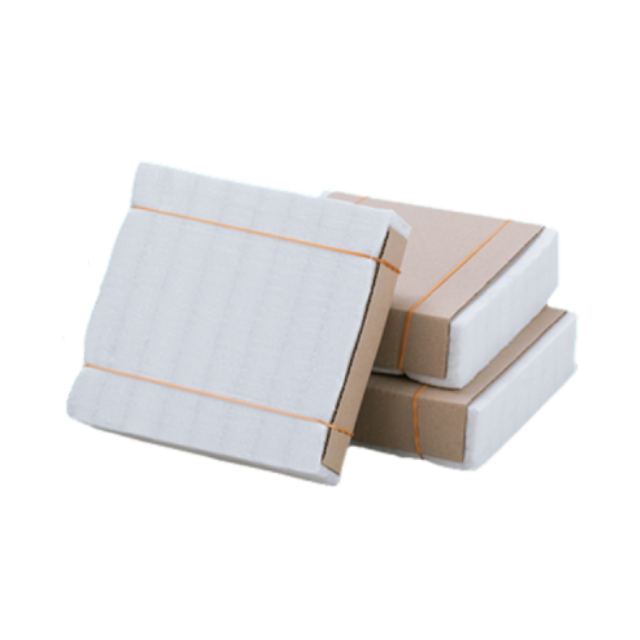

Packaging

|

Size (mm)

|

Quantity

per carton

|

Carton

|

||

|

Thickness

|

Width

|

Length

|

Size (mm)

|

|

|

6

|

600

|

7200

|

4

|

520×520×620

|

|

12.5

|

2

|

660×330×620

|

||

|

25

|

1

|

470×470×620

|

||

|

50

|

600

|

3600

|

1

|

470×470×620

|

|

6

|

600

|

1200

|

20

|

1220×620×140

|

|

12.5

|

20

|

1220×620×270

|

||

|

25

|

10

|

|||

|

50

|

5

|

|||

Data shown are typical values obtained in accordance with accepted test methods.

They are provided for your reference only and are subject to change without notice.

Q&A

Catalog

Contact

【Call】

Branch Office: Overseas Department,

Tokyo, Osaka, Nagoya, Kyushu