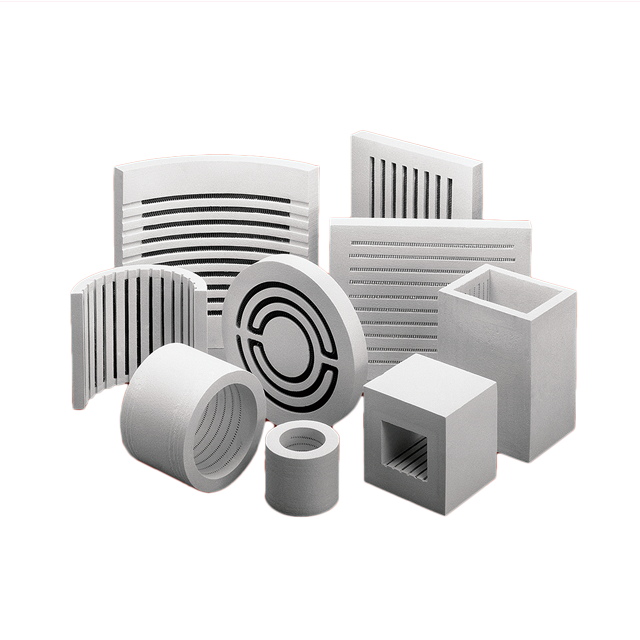

ISOTAP(Dry)F tamp (Wet)

Ceramic Fiber Base Monolithic Refractory ISOTAP series

ISOTAP series are ceramic fiber based monolithic refractories. ISOTAP series is available on tapping. Their bulk density after drying ranges around 500 ~ 1000 kg/m³.

Typical Applications

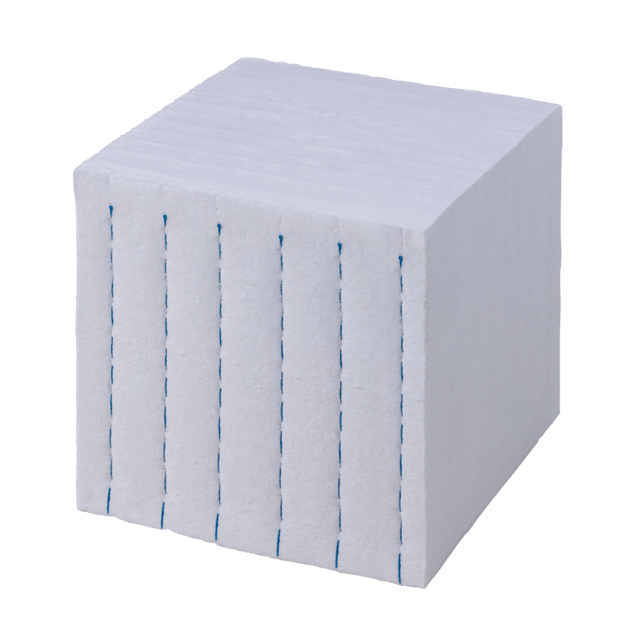

1. Same as other unshared refractories, two kinds of monolithic refractories are available; one is a dry type; the other is a waterbearing wet type for straight use.

2. It is lightweight, and has a high insulating capacity and good adhesiveness and convenient for the areas with limited accessibility and workability.

3. Compared with other ceramic fiber products, ISOTAP series have extra high strength due to refractory filler added, and moldability due to binder and viscous material added.

4. ISOTAP has high volume stability at drying and heating.

Quality

| Type | Dry | Dry | Dry | |

| Product name | ISOTAP

F-12 |

ISOTAP

F-13 |

ISOTAP

F-14 |

|

| Max. Service Temperature(℃) | 1,200 | 1,300 | 1,400 | |

| Bulk Density (kg/m³) | After drying at 105℃ | 810 | 780 | 1,060 |

| after firing

at Max.service.Temp. |

720 | 700 | 1,000 | |

| Modulus of Rupture (MPa) | After drying at 105℃ | 1.7 | 1 | 1.6 |

| after firing

at Max.service.Temp. |

0.7 | 0.6 | 0.8 | |

| Linear Shrinkage (%) | After drying at 105℃ | 0 | 0 | 0 |

| after firing

at Max.service.Temp. |

-0.8 | -0.8 | -0.9 | |

| Thermal Conductivity (W/(m・K)) JIS A1412-1 ※Calculation value |

at 100℃ | 0.1 | 0.12 | 0.16 |

| at 350℃ | 0.15 | 0.15 | 0.19 | |

| at 700℃ | 0.17 | 0.19 | 0.22 | |

| Chemical Composition (%) |

Al₂O₃ | 54 | 63 | 74 |

| SiO₂ | 30 | 26 | 20 | |

| Water rates recommended (%) | 100~110 | 100~110 | 60~65 | |

| Quantity required (ton/m³) | 0.62~0.75 | 0.60~0.72 | 1.02~1.08 | |

| Quantity per Bag or Can (kg) | 15 | |||

| Packaging | Paper Bag | |||

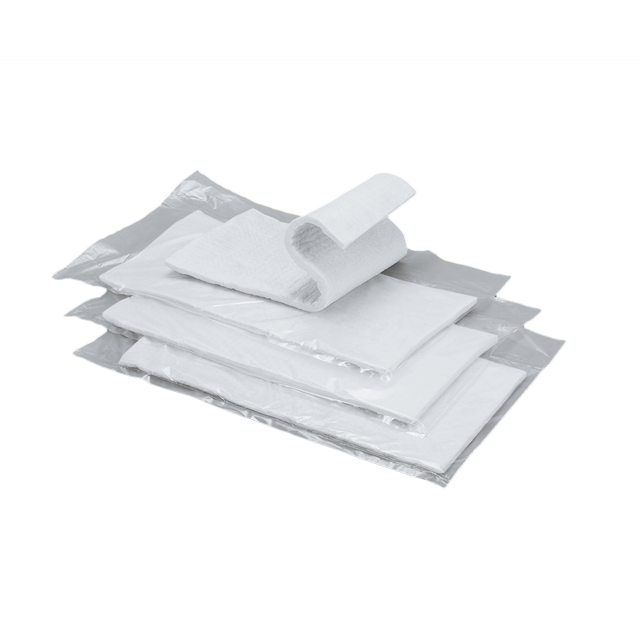

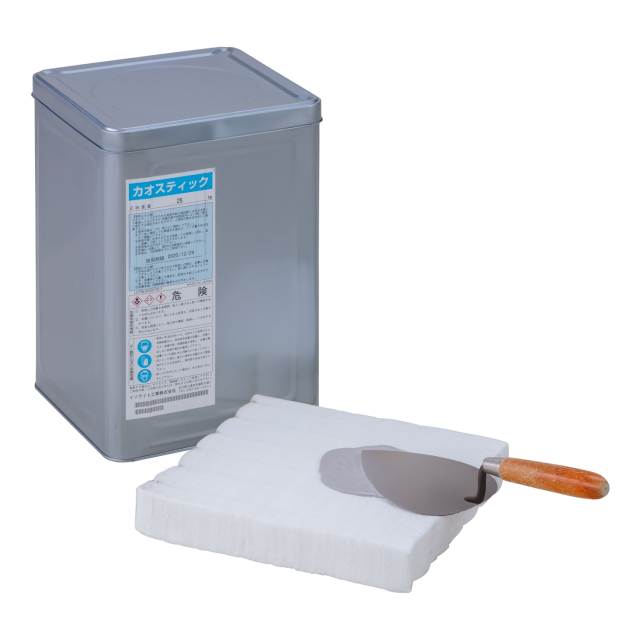

| Type | Wet | Wet | Wet | Wet | |

| Product name |

F tamp

12W

|

F tamp

12WP

|

F tamp

13W

|

F tamp

AL-70W

|

|

|

Max. Service Temperature(℃)

|

1200

|

1200

|

1300

|

1000

|

|

|

Bulk Density (kg/m³)

|

After drying

|

330 | 615 | 390 | 520 |

|

after firing at Max.service.Temp.

|

350 | 645 |

450

|

510

|

|

|

Modulus of Rupture (MPa)

|

After drying

|

0.41 | 0.49 |

0.52

|

0.58

|

|

after firing at Max.service.Temp.

|

0.35

|

0.39 |

0.40

|

0.45

|

|

|

Linear Shrinkage (%)

|

After drying

|

0.0 |

0.0

|

0.0 | 0.0 |

| after firing at Max.service.Temp. |

-3.3

|

-1.5

|

-5.0

|

-0.5

|

|

| Thermal Conductivity (W/(m・K)) |

at 800℃

|

0.21 |

0.26

|

0.22

|

0.24

|

|

at 1000℃

|

0.26

|

0.30

|

0.27

|

0.28

|

|

|

Chemical Composition

(%) |

Al₂O₃

|

40 | 73 |

47

|

15

|

|

SiO₂

|

59

|

26

|

52 | 53 | |

|

Quantity per plastic container (kg)

|

15

|

||||

|

Packaging

|

plastic container

|

||||

Catalog

Contact

【Call】

Branch Office: Overseas Department,

Tokyo, Osaka, Nagoya, Kyushu