Research and Development

Ceramic molding technology

The advantages of Isolite molding technology are light weight, low thermal conductivity, and the ability to support complex shapes.

Ceramic fiber products, in particular, possess excellent formability and control bulk density and shape can be freely controlled according to the purpose. In addition to plates, cylinders and granules, they can be molded into more complicated shapes.

On the production line, we have established molding technology for thicknesses of up to 150 mm (plate), and more precise machining is possible at the laboratory. This characteristic can be utilized as a technology that enables molding together with heater wires, which is used for manufacturing panel heaters.

Isolite uses wet and dry moulding methods technology depending on the product.

<Examples of products utilizing molding technology>

- Ultra-low thermal conductivity insulating materials (LTC board)

- Cylindrical material, sealing material, panel heaters, compacts for molten metal

- Insulating firebricks (Group A, Group B, Group C, LBK Series, High Alumina IFB)

- High-temperature dust collecting filter (ISOFIL)

- Isolite CG

- Wet felt

<Introduction to ultra low thermal conductivity technology>

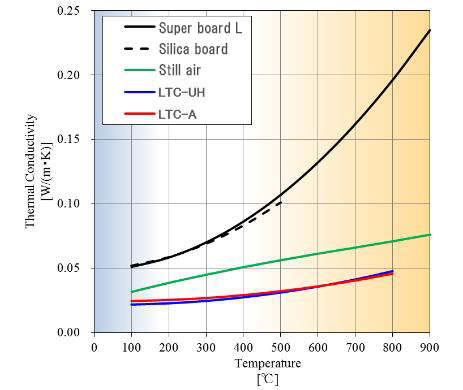

LTC board is microporous insulation material with numerous fine pores made of nanoparticles and inorganic fibers. By optimizing submicron order pores and infrared emissivity with nanoparticles, we have made it possible to achieve a lower thermal conductivity than still air. The lack of strength and durability due to the nano-sized raw material is eliminated with the addition of reinforcing material and manufacturing technology, and its strength exceeds that of conventional products.

With excellent workability, processability and water resistance feature, LTC board exhibits energy saving effects through ultra-low thermal conductivity in various environments, responding to more complex and advanced needs.

-

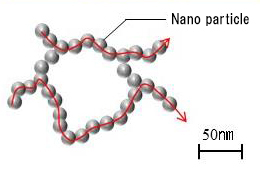

①Heat conduction

Heat conduction was controlled by nanoparticles which are decreased limitlessly in contact area and cross section

Heat conduction was controlled by nanoparticles which are decreased limitlessly in contact area and cross section -

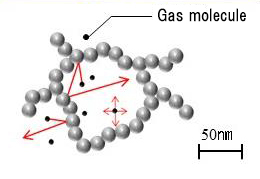

②Convection

Convection was controlled by pore diameter which is smaller than collision distance of gas molecules at atmospheric pressure

Convection was controlled by pore diameter which is smaller than collision distance of gas molecules at atmospheric pressure -

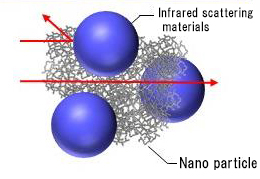

③Heat radiation

Heat radiation is dominant in the high temperature range

Heat radiation is dominant in the high temperature range

Heat radiation was controlled which reduced infrared emissivity by infrared scattering materials

※The illustration shown is a concept image

Ceramic composite molding technology

There are three main technologies for molding composites.

- Molding by mixing functional materials (particles, etc.) as raw materials It results in a compact in which functional substances are uniformly dispersed. Basically, any substance can be composited, including organics, inorganics and metals.

- The molded product fills the periphery of the functional substance (electric wire, etc.)

It becomes a molded product integrated with the functional substance. - The molded product is impregnated with a functional substance (a liquid such as a catalyst)

It becomes a molded product with a special function. As it is porous, it is used for various types of filter.

Examples of products in which composite technology is used

- Panel heater (Composite of ceramic fibers and heating wire)

- ISOPLATON (Composite of ceramic fibers and inorganic particles)

- TBS