ISOPLATON

ISOPLATON

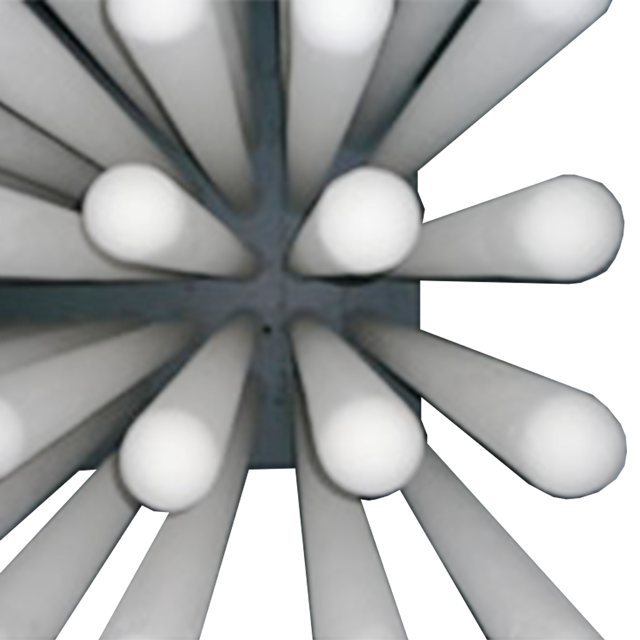

Made of ceramic fibers and alumina particles, Isolite’s ISOPLATON is a setter (jig) to be used in kilns for firing electronic components, etc. Having excellent features of lightweight, dimensional accuracy, superior resistance against thermal shock, ISOPLATON are available, in addition to its plain shape, in various shapes with legs, or grooves, etc. to meet the needs of automatic firing process and shorter operation cycle, offering extra high cost-performance of the product.

・Excellent permeability

・Excellent binder removability

・Strong against thermal shook

・Low heat capacity

・No warping

・Available in various sizes and shapes

・Lightweight and easy handling

Typical Application

1. For firing piezoelectic ceramic filters

2. For firing stacked LC filters

3. For firing stacked type condensers

Sizes

| Size(mm) | Thickness | Width | Length |

| Standard | 5 | 150 | 150 |

| Max | 50 | 300 | 600 |

Quality

| ISOPLATON | E3 | P1 | M2 | A98 | S1 | |

| Max. Service Temp. (℃) | 1150 | 1250 | 1200 | 1150 | 1500 | |

| Bulk Density (Kg/m3) | 800 | 1100 | 1150 | 1150 | 1250 | |

| Porosity (%) | 75 | 71.1 | 65 | 69 | 58 | |

| Permeability Rate (×10-8 cm2) | 5 | 1.6 | 1.5 | 1.2 | 1.2 | |

| Modulus of Rupture (MPa) R.T. | 8 | 10 | 11 | 7.5 | 9 | |

| Chemical Composition (Wt%) | SiO₂ | 18.1 | 16 | 34.5 | 1.9 | 20.1 |

| Al₂O₃ | 81.5 | 84 | 62 | 97.7 | 79.6 | |

| MgO | – | – | 3.5 | – | – | |

| Others | 0.4 | – | – | 0.4 | 0.3 | |

| Crystalline Phase | Mullite Corundum |

Mullite Corundum |

Mullite Corundum |

Corundum | Mullite Corundum |

|

| Thermal Expansion (%) at 1000℃ | 0.7 | 0.77 | 0.44 | 0.78 | 0.56 | |

| Surface Roughness Ra (μ m) | 6.8 | 5.8 | 6.5 | 5.8 | 6.0 | |

| Coating | MgO | – | ○ | – | – | ○ |

| ZrO₂ | – | ○ | – | – | – | |

| MgO | – | ○ | – | – | – | |

Data shown are typical values obtained in accordance with accepted test methods.

They are provided for your reference only and are subject to change without notice.

Contact

【Call】

Branch Office: Overseas Department,

Tokyo, Osaka, Nagoya, Kyushu